Brand sort

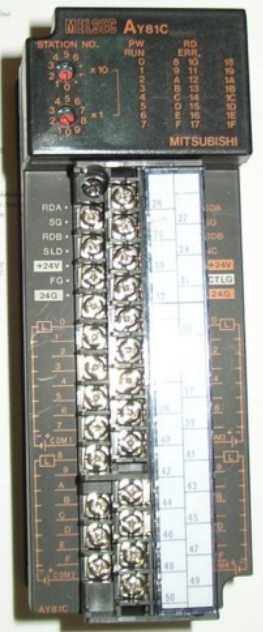

MITSUBISHI MITSUBISHI AY81C Price

Brand:

MITSUBISHI

Country: JAPAN

Name: Bidirectional thyristor output module

Model: AY81C

Market price: U.S.$ 1238.98

(The following are the market open price not sales price!)

(The following are the market open price not sales price!)

MITSUBISHI AY81C

Servo motor series: low inertia, medium / high power.

Rated output: 1.5kw.

Rated speed: 3000r/min.

Electromagnetic brake: with.

Shaft end specification: Standard (straight axis).

Voltage: 400V level.

Features: low inertia for high speed / acceleration and deceleration operation occasions.

IP level: IP67.

Application example:

1, food processing machinery.

2, printing machine.

3, injection molding machine (11KW, 15KW) AY81C

4, large press machine (11KW, 15KW).

The protection level of the HF-SP/HF-JP series servo motor is IP67 (except the shaft part).

Low inertia of the power servo motor (0.5kW ~ 9kW), the maximum speed: 6000r/min (rated speed: 3000r/min),

Suitable for high frequency positioning and acceleration / deceleration operations, especially for food processing machines and printing machines.

Low inertia, high power, no cooling fan servo motor (11kW and 15kW), maximum speed: 3000r/min (rated speed: 1500r/min).

The motor structure is more compact due to the adoption of the non cooling fan design, and the connection is reduced by using the power source connector.

(compared with the HF-LP series servo motor with the same power, the volume is reduced by about 46%, and the weight is reduced by about 34%,

Suitable for high frequency positioning and acceleration / deceleration operations, especially for injection molding machines and large presses.

HF-JP703 (4) /903 (4) maximum speed: 5000r/min. The connector is converted to a screw relay terminal.For HF-KP/HF-MP seriesSpecifications: FX0N-65EC.

Cable extending unit.

Length 65CM. Output points: 8 points.

Output voltage and current: AC100 ~ 240V, 0.6A/1 point, 4A/1 public end.

Response time: 0.5Hz+1ms.

Output form: bidirectional thyristor output.

8 point /1 a public side.

26 point terminal station.

Number of stations: 1 stops.

Type remote I/O units outside of the panel (optical data connection).

Equipment layer / field bus CC-Link device layer is the PLC and other control devices and sensors and drive devices connected to the field network,

Network for the lowest layer of the whole network system.

Using CC-Link field bus connection, the number of wiring is greatly reduced,

Improve the maintainability of the system.

And, not just the amount of data ON/OFF and other switches,

Can also be connected to the ID system, bar code reader, inverter, man-machine interface and other intelligent devices,

From the completion of a variety of data communication, the management of the terminal production information can be realized,

On the centralized management of the state of the machine movement,

Make maintenance work efficiency also greatly improved.

Q series PLC in the use of CC-Link function better,

And easier to use.

Mitsubishi Co PLC network inherited the traditional use of the MELSEC network,

And make it better in terms of performance, function, easy to use etc..

Provides a layer of three layers of clear network, to provide the most suitable network products for a variety of uses.

The information layer /Ethernet (Ethernet) information layer is the highest level of the network system,

Mainly in the PLC, the device controller and production management with PC transmission between production management information, quality management information and the operation of equipment, etc.,

Information layer using the most common Ethernet.

It is not only able to connect the PC system UNIX, windows system, etc.,

And can connect a variety of FA devices.

The Ethernet module has the function of Internet e-mail receiving and sending,

The user can send and receive the production information conveniently in any place of the world,

Build a remote monitoring management system.

At the same time, the use of the Internet FTP server functions and MELSEC protocol can be very easy to achieve the program upload / download and transfer of information.

AY81C Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=AY81C&select=5

Rated output: 1.5kw.

Rated speed: 3000r/min.

Electromagnetic brake: with.

Shaft end specification: Standard (straight axis).

Voltage: 400V level.

Features: low inertia for high speed / acceleration and deceleration operation occasions.

IP level: IP67.

Application example:

1, food processing machinery.

2, printing machine.

3, injection molding machine (11KW, 15KW) AY81C

4, large press machine (11KW, 15KW).

The protection level of the HF-SP/HF-JP series servo motor is IP67 (except the shaft part).

Low inertia of the power servo motor (0.5kW ~ 9kW), the maximum speed: 6000r/min (rated speed: 3000r/min),

Suitable for high frequency positioning and acceleration / deceleration operations, especially for food processing machines and printing machines.

Low inertia, high power, no cooling fan servo motor (11kW and 15kW), maximum speed: 3000r/min (rated speed: 1500r/min).

The motor structure is more compact due to the adoption of the non cooling fan design, and the connection is reduced by using the power source connector.

(compared with the HF-LP series servo motor with the same power, the volume is reduced by about 46%, and the weight is reduced by about 34%,

Suitable for high frequency positioning and acceleration / deceleration operations, especially for injection molding machines and large presses.

HF-JP703 (4) /903 (4) maximum speed: 5000r/min. The connector is converted to a screw relay terminal.For HF-KP/HF-MP seriesSpecifications: FX0N-65EC.

Cable extending unit.

Length 65CM. Output points: 8 points.

Output voltage and current: AC100 ~ 240V, 0.6A/1 point, 4A/1 public end.

Response time: 0.5Hz+1ms.

Output form: bidirectional thyristor output.

8 point /1 a public side.

26 point terminal station.

Number of stations: 1 stops.

Type remote I/O units outside of the panel (optical data connection).

Equipment layer / field bus CC-Link device layer is the PLC and other control devices and sensors and drive devices connected to the field network,

Network for the lowest layer of the whole network system.

Using CC-Link field bus connection, the number of wiring is greatly reduced,

Improve the maintainability of the system.

And, not just the amount of data ON/OFF and other switches,

Can also be connected to the ID system, bar code reader, inverter, man-machine interface and other intelligent devices,

From the completion of a variety of data communication, the management of the terminal production information can be realized,

On the centralized management of the state of the machine movement,

Make maintenance work efficiency also greatly improved.

Q series PLC in the use of CC-Link function better,

And easier to use.

Mitsubishi Co PLC network inherited the traditional use of the MELSEC network,

And make it better in terms of performance, function, easy to use etc..

Provides a layer of three layers of clear network, to provide the most suitable network products for a variety of uses.

The information layer /Ethernet (Ethernet) information layer is the highest level of the network system,

Mainly in the PLC, the device controller and production management with PC transmission between production management information, quality management information and the operation of equipment, etc.,

Information layer using the most common Ethernet.

It is not only able to connect the PC system UNIX, windows system, etc.,

And can connect a variety of FA devices.

The Ethernet module has the function of Internet e-mail receiving and sending,

The user can send and receive the production information conveniently in any place of the world,

Build a remote monitoring management system.

At the same time, the use of the Internet FTP server functions and MELSEC protocol can be very easy to achieve the program upload / download and transfer of information.

AY81C Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=AY81C&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Bidirectional thyristor output module

AY23

Output points: 32 points.

Voltage: AC100

MITSUBISHI

Bidirectional thyristor output module

AY22

Output points: 16 points.

Voltage: AC100

MITSUBISHI

Transistor output module

AY80EP

Output points: 16 points.

Voltage: DC12/

MITSUBISHI

Transistor output module

AY40P

Output points: 16 points.

Voltage: DC12/

Related download

next one:

next one:  Last one:

Last one: