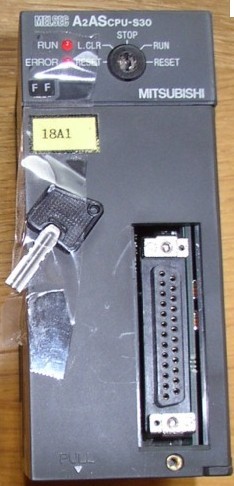

A2ASCPU-S30 CPU unit

MITSUBISHI A2ASCPU-S30 Manual And Instructions

A2ASCPU-S30 datasheetPDF datasheet

A2ASCPU-S30 Common InstructionsProgramming Manual

A2ASCPU-S30 User's Manual

A2ASCPU-S30 User's Manual

A2ASCPU-S30 HardwareUser's Manual

A2ASCPU-S30 Dedicated InstructionsProgramming Manual

A2ASCPU-S30 FundamentalsProgramming Manual

MITSUBISHI A2ASCPU-S30 Product information and technical parameters:

Brand: MITSUBISHI

Name: CPU unit

Model: A2ASCPU-S30

I/O points: 1024.

Processing speed: sec/ 0.15u step.

Memory capacity: 256K bytes.

Program capacity: 30K step.

PLC programming is a digital computing operation of the electronic system,

Designed for applications in industrial environments.

It uses programmable memory,

An instruction used to perform logical operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through the digital, analog input and output, control of various types of machinery or production process.

Programmable controller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions.

...More relevant models >>>>

A2ASCPU-S30 datasheetPDF datasheet

A2ASCPU-S30 Common InstructionsProgramming Manual

A2ASCPU-S30 User's Manual

A2ASCPU-S30 User's Manual

A2ASCPU-S30 HardwareUser's Manual

A2ASCPU-S30 Dedicated InstructionsProgramming Manual

A2ASCPU-S30 FundamentalsProgramming Manual

MITSUBISHI A2ASCPU-S30 Product information and technical parameters:

Brand: MITSUBISHI

Name: CPU unit

Model: A2ASCPU-S30

I/O points: 1024.

Processing speed: sec/ 0.15u step.

Memory capacity: 256K bytes.

Program capacity: 30K step.

PLC programming is a digital computing operation of the electronic system,

Designed for applications in industrial environments.

It uses programmable memory,

An instruction used to perform logical operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through the digital, analog input and output, control of various types of machinery or production process.

Programmable controller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions.

Output type: relay.

Output points: 12 points.

Load voltage: AC240/DC24.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 4.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions A2ASCPU-S30 A2ASCPU-S30

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time A2ASCPU-S30.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced A2ASCPU-S30. CPU:A2SHCPU PLC is the same.

PLC program capacity: 30K step.

I/O points: 1024 points.

Processing speed (sequential order): 0.25 s/ step.

Control axis: up to 8.

Servo program capacity: 13K step.

Servo amplifier: SSCNET connected external servo amplifier.

PLC programming has a wide range of applications, powerful, easy to use, has become one of the main devices of modern industrial automation,

In all areas of industrial production has been widely used,

Applications in other areas (such as civil and home automation) have also been rapidly developed.

It uses programmable memory,

An instruction used to perform logical operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through digital, analog input and output,

Control of various types of machinery or production processes. Programmable controller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions A2ASCPU-S30.

As can be seen from the above definition, PLC is a program to change the control function of the industrial conttrol computer,

In addition to the completion of a wide variety of control functions, as well as with other computer communications networking features A2ASCPU-S30.

Output points: 12 points.

Load voltage: AC240/DC24.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 4.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions A2ASCPU-S30 A2ASCPU-S30

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time A2ASCPU-S30.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced A2ASCPU-S30. CPU:A2SHCPU PLC is the same.

PLC program capacity: 30K step.

I/O points: 1024 points.

Processing speed (sequential order): 0.25 s/ step.

Control axis: up to 8.

Servo program capacity: 13K step.

Servo amplifier: SSCNET connected external servo amplifier.

PLC programming has a wide range of applications, powerful, easy to use, has become one of the main devices of modern industrial automation,

In all areas of industrial production has been widely used,

Applications in other areas (such as civil and home automation) have also been rapidly developed.

It uses programmable memory,

An instruction used to perform logical operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through digital, analog input and output,

Control of various types of machinery or production processes. Programmable controller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions A2ASCPU-S30.

As can be seen from the above definition, PLC is a program to change the control function of the industrial conttrol computer,

In addition to the completion of a wide variety of control functions, as well as with other computer communications networking features A2ASCPU-S30.

...More relevant models >>>>

Related download

Last one:

Last one:  next one:

next one: