AJ35PTC-CNV-GI Melsecnet module

MITSUBISHI AJ35PTC-CNV-GI Manual And Instructions

AJ35PTC-CNV-GI datasheetPDF datasheet

MITSUBISHI AJ35PTC-CNV-GI Product information and technical parameters:

Brand: MITSUBISHI

Name: Melsecnet module

Model: AJ35PTC-CNV-GI

MELSECNET/MINI (-S3) data link system, A2C system transfer converter.

Twisted pair cable -GI optical fiber cable.

MITSUBISHI PLC protection and chain procedures.

Protection and chain is an indispensable part of the program, must be carefully considered.

It can avoid the control logic confusion caused by illegal operations.

MITSUBISHI PLC initialization procedure. After MITSUBISHI PLC on power, the general need to do some of the initial operation,

In order to start making necessary preparations, to avoid the wrong operation of the system.

The main contents of the initialization program are: to some data area, counter and so on,

Data needed to restore some of the data area,

Set or reset some relays,

For some initial state display, etc..

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation.

...More relevant models >>>>

AJ35PTC-CNV-GI datasheetPDF datasheet

MITSUBISHI AJ35PTC-CNV-GI Product information and technical parameters:

Brand: MITSUBISHI

Name: Melsecnet module

Model: AJ35PTC-CNV-GI

MELSECNET/MINI (-S3) data link system, A2C system transfer converter.

Twisted pair cable -GI optical fiber cable.

MITSUBISHI PLC protection and chain procedures.

Protection and chain is an indispensable part of the program, must be carefully considered.

It can avoid the control logic confusion caused by illegal operations.

MITSUBISHI PLC initialization procedure. After MITSUBISHI PLC on power, the general need to do some of the initial operation,

In order to start making necessary preparations, to avoid the wrong operation of the system.

The main contents of the initialization program are: to some data area, counter and so on,

Data needed to restore some of the data area,

Set or reset some relays,

For some initial state display, etc..

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation.

DC input points: 4 points.

Input voltage and current: 7mA, DC24V.

Input response time: 10ms.

4 point /1 a public side.

Positive pole sharing.

Output points: 4 points.

Output voltage and current: DC24V.

Output response time: 2ms.

4 point /1 a public side.

Output form: transistor output, leakage type.

24 point terminal station AJ35PTC-CNV-GI.

MITSUBISHI PLC protection and chain procedures.

Protection and chain is an indispensable part of the program, must be carefully considered AJ35PTC-CNV-GI

It can avoid the control logic confusion caused by illegal operations.

MITSUBISHI PLC initialization procedure. After MITSUBISHI PLC on power, the general need to do some of the initial operation,

In order to start making necessary preparations, to avoid the wrong operation of the system AJ35PTC-CNV-GI.

The main contents of the initialization program are: to some data area, counter and so on,

Data needed to restore some of the data area,

Set or reset some relays,

For some initial state display, etc..

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program AJ35PTC-CNV-GI.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation. AC input points: 8 points.

Input voltage and current: 120V ~ 10mA AC100.

Response time: 25ms.

8 point /1 a public side.

26 point terminal station.

Number of stations: 1 stops.

Type remote I/O units outside of the panel (optical data connection).

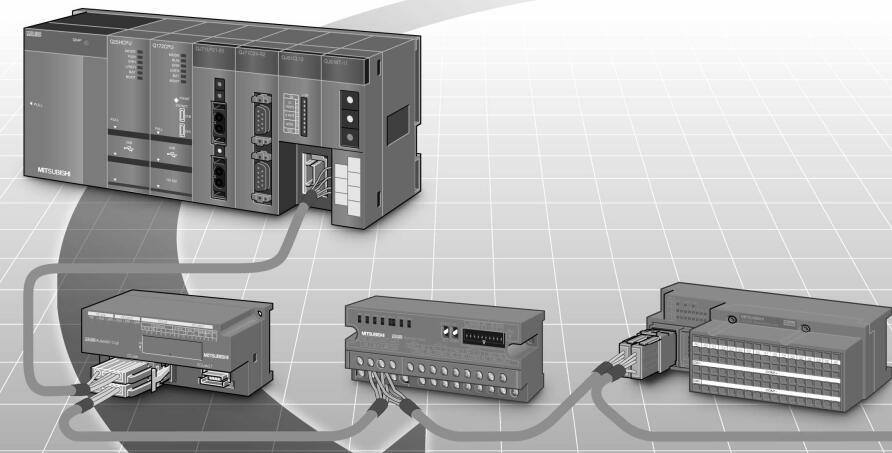

Equipment layer / field bus CC-Link device layer is the PLC and other control devices and sensors and drive devices connected to the field network,

Network for the lowest layer of the whole network system.

Using CC-Link field bus connection, the number of wiring is greatly reduced,

Improve the maintainability of the system.

And, not just the amount of data ON/OFF and other switches,

Can also be connected to the ID system, bar code reader, inverter, man-machine interface and other intelligent devices,

From the completion of a variety of data communication, the management of the terminal production information can be realized,

On the centralized management of the state of the machine movement,

Make maintenance work efficiency also greatly improved.

Q series PLC in the use of CC-Link function better,

And easier to use.

Mitsubishi Co PLC network inherited the traditional use of the MELSEC network,

And make it better in terms of performance, function, easy to use etc..

Provides a layer of three layers of clear network, to provide the most suitable network products for a variety of uses.

The information layer /Ethernet (Ethernet) information layer is the highest level of the network system,

Mainly in the PLC, the device controller and production management with PC transmission between production management information, quality management information and the operation of equipment, etc.,

Information layer using the most common Ethernet.

It is not only able to connect the PC system UNIX, windows system, etc.,

And can connect a variety of FA devices.

The Ethhernet module has the function of Internet e-mail receiving and sending,

The user can send and receive the production information conveniently in any place of the world,

Build a remote monitoring management system AJ35PTC-CNV-GI.

At the same time, tthe use of the Internet FTP server functions and MELSEC protocol can be very easy to achieve the program upload / download and transfer of information AJ35PTC-CNV-GI.

Input voltage and current: 7mA, DC24V.

Input response time: 10ms.

4 point /1 a public side.

Positive pole sharing.

Output points: 4 points.

Output voltage and current: DC24V.

Output response time: 2ms.

4 point /1 a public side.

Output form: transistor output, leakage type.

24 point terminal station AJ35PTC-CNV-GI.

MITSUBISHI PLC protection and chain procedures.

Protection and chain is an indispensable part of the program, must be carefully considered AJ35PTC-CNV-GI

It can avoid the control logic confusion caused by illegal operations.

MITSUBISHI PLC initialization procedure. After MITSUBISHI PLC on power, the general need to do some of the initial operation,

In order to start making necessary preparations, to avoid the wrong operation of the system AJ35PTC-CNV-GI.

The main contents of the initialization program are: to some data area, counter and so on,

Data needed to restore some of the data area,

Set or reset some relays,

For some initial state display, etc..

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program AJ35PTC-CNV-GI.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation. AC input points: 8 points.

Input voltage and current: 120V ~ 10mA AC100.

Response time: 25ms.

8 point /1 a public side.

26 point terminal station.

Number of stations: 1 stops.

Type remote I/O units outside of the panel (optical data connection).

Equipment layer / field bus CC-Link device layer is the PLC and other control devices and sensors and drive devices connected to the field network,

Network for the lowest layer of the whole network system.

Using CC-Link field bus connection, the number of wiring is greatly reduced,

Improve the maintainability of the system.

And, not just the amount of data ON/OFF and other switches,

Can also be connected to the ID system, bar code reader, inverter, man-machine interface and other intelligent devices,

From the completion of a variety of data communication, the management of the terminal production information can be realized,

On the centralized management of the state of the machine movement,

Make maintenance work efficiency also greatly improved.

Q series PLC in the use of CC-Link function better,

And easier to use.

Mitsubishi Co PLC network inherited the traditional use of the MELSEC network,

And make it better in terms of performance, function, easy to use etc..

Provides a layer of three layers of clear network, to provide the most suitable network products for a variety of uses.

The information layer /Ethernet (Ethernet) information layer is the highest level of the network system,

Mainly in the PLC, the device controller and production management with PC transmission between production management information, quality management information and the operation of equipment, etc.,

Information layer using the most common Ethernet.

It is not only able to connect the PC system UNIX, windows system, etc.,

And can connect a variety of FA devices.

The Ethhernet module has the function of Internet e-mail receiving and sending,

The user can send and receive the production information conveniently in any place of the world,

Build a remote monitoring management system AJ35PTC-CNV-GI.

At the same time, tthe use of the Internet FTP server functions and MELSEC protocol can be very easy to achieve the program upload / download and transfer of information AJ35PTC-CNV-GI.

...More relevant models >>>>

Last one: MITSUBISHI Melsecnet module AJ35PTC-CNV-SI

Last one: MITSUBISHI Melsecnet module AJ35PTC-CNV-SI next one: MITSUBISHI Melsecnet module AJ35PP-CNV-SI

next one: MITSUBISHI Melsecnet module AJ35PP-CNV-SI

Related download