Home

>> Products

>> MITSUBISHI

>> Q series PLC

>> Temperature regulation module

>> Q64TCRTBW Platinum resistance temperature control module

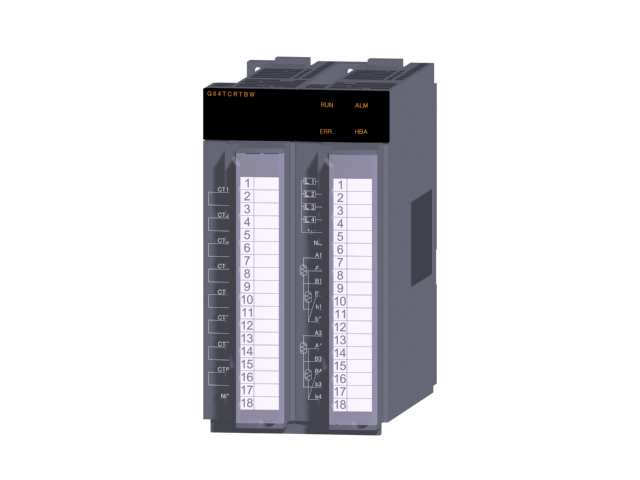

Q64TCRTBW Platinum resistance temperature control module

MITSUBISHI Q64TCRTBW Manual And Instructions

Q64TCRTBW datasheetPDF datasheet

Q64TCRTBW datasheetPDF datasheet

MITSUBISHI Q64TCRTBW Product information and technical parameters:

Brand: MITSUBISHI

Name: Platinum resistance temperature control module

Model: Q64TCRTBW

Input: 4 channels.

Platinum resistance (Pt100; JPt100).

Heater disconnection detection function.

Sampling period: 0.5s/4 channel.

18 point terminal table x2.

Peak current suppression.

Can prevent the simultaneous opening of the output to control the peak current, which is helpful for saving energy and reducing the operation cost.

Heating function at the same time.

The multiple loop can reach the set value at the same time to carry out the uniform temperature control,

Helps to prevent no-load and effective energy saving and reduce operating costs.

Automatic adjustment function.

The PID constant can be adjusted automatically in the control process.

Automatic adjustment of cost (time, material and electrical energy) can be reduced.

Can be flexible in various settings, to achieve the best temperature control of the temperature control module.

Equipment for high temperature control stability of extrusion molding machine,

The temperature regulating module has the function of preventing overheating and preventing over cooling.

According to the control object device, select the standard control (heating or cooling) or the heating and cooling control (heating and cooling) mode.

In addition, the mixed control mode (combined with the standard control and heating - cooling control) can be selected.

...More relevant models >>>>

Q64TCRTBW datasheetPDF datasheet

Q64TCRTBW datasheetPDF datasheet

MITSUBISHI Q64TCRTBW Product information and technical parameters:

Brand: MITSUBISHI

Name: Platinum resistance temperature control module

Model: Q64TCRTBW

Input: 4 channels.

Platinum resistance (Pt100; JPt100).

Heater disconnection detection function.

Sampling period: 0.5s/4 channel.

18 point terminal table x2.

Peak current suppression.

Can prevent the simultaneous opening of the output to control the peak current, which is helpful for saving energy and reducing the operation cost.

Heating function at the same time.

The multiple loop can reach the set value at the same time to carry out the uniform temperature control,

Helps to prevent no-load and effective energy saving and reduce operating costs.

Automatic adjustment function.

The PID constant can be adjusted automatically in the control process.

Automatic adjustment of cost (time, material and electrical energy) can be reduced.

Can be flexible in various settings, to achieve the best temperature control of the temperature control module.

Equipment for high temperature control stability of extrusion molding machine,

The temperature regulating module has the function of preventing overheating and preventing over cooling.

According to the control object device, select the standard control (heating or cooling) or the heating and cooling control (heating and cooling) mode.

In addition, the mixed control mode (combined with the standard control and heating - cooling control) can be selected.

Control axis: maximum 8 axes.

Greater flexibility.

PLC control and motion control using independent CPU, optimize the system configuration.

More than 4 CPU modules can be freely selected in multi CPU system.

MITSUBISHI SSCNET control function.

By using the high speed serial communication mode, we can easily construct the synchronization system of the servo motor Q64TCRTBW.

The motion controller and the servo amplifier can be quickly connected by a connector, and the connection is simplified Q64TCRTBW

Each 1 CPU can control up to 32 axes at the same time.

Can control the small capacity from 10W to 55KW large capacity servo motor.

Through the use of digital oscilloscope function, can be used to control the power distance, speed, position and other motor information monitoring Q64TCRTBW. Extended SRAM card 2MB

Better user experience data recording function.

Easy to record, no need to program.

Simply through the special configuration tool wizard to easily complete the settings,

The collected data can be saved in CSV format to SD storage card.

Can be effectively used to save the CSV file to facilitate the creation of a variety of reference materials,

Including daily reports, generate reports and general reports Q64TCRTBW.

These data can be applied to the data analysis, tracing, etc..Output points: 16 points.

Output voltage and current: DC12~24V; 0.1A/ point; 1.6A/ common.

OFF leakage current: 0.1mA;

Response time: 1ms; 1 point 16 public end; leaky type.

18 point spring clip connection terminal.

With heat protection.

With short circuit protection.

With the surge absorber.

Continue to go beyond, to climb the peak of Q series.

Strengthen security function.

Can be set up to 32 characters of the file password.

In addition to the English letters, numbers, but also the use of special characters,

To further enhance the security of the password.

In addition, only pre registered devices are allowed to access CPU,

To intercept unauthorized access to unauthorized users.

Therefore, it is important to prevent the outflow of important program assets and protect intellectual property rights.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow and motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields.

Can also be used in combination with the CPU module to achieve appropriate control.

Easy connection programming tool via ethernet.

Programming toolls (Works2 GX, Developer GX) and CPU direct connection (1 to 1),

No need to carry out the IP address settings Q64TCRTBW. And there is no need to select the cable, the straight line and the cross line can be used.

Therefore, this connection method annd the use of USB, can easily communicate with the CPU,

Even the operators are not familiar with the network settings can easily establish a connection Q64TCRTBW.

Greater flexibility.

PLC control and motion control using independent CPU, optimize the system configuration.

More than 4 CPU modules can be freely selected in multi CPU system.

MITSUBISHI SSCNET control function.

By using the high speed serial communication mode, we can easily construct the synchronization system of the servo motor Q64TCRTBW.

The motion controller and the servo amplifier can be quickly connected by a connector, and the connection is simplified Q64TCRTBW

Each 1 CPU can control up to 32 axes at the same time.

Can control the small capacity from 10W to 55KW large capacity servo motor.

Through the use of digital oscilloscope function, can be used to control the power distance, speed, position and other motor information monitoring Q64TCRTBW. Extended SRAM card 2MB

Better user experience data recording function.

Easy to record, no need to program.

Simply through the special configuration tool wizard to easily complete the settings,

The collected data can be saved in CSV format to SD storage card.

Can be effectively used to save the CSV file to facilitate the creation of a variety of reference materials,

Including daily reports, generate reports and general reports Q64TCRTBW.

These data can be applied to the data analysis, tracing, etc..Output points: 16 points.

Output voltage and current: DC12~24V; 0.1A/ point; 1.6A/ common.

OFF leakage current: 0.1mA;

Response time: 1ms; 1 point 16 public end; leaky type.

18 point spring clip connection terminal.

With heat protection.

With short circuit protection.

With the surge absorber.

Continue to go beyond, to climb the peak of Q series.

Strengthen security function.

Can be set up to 32 characters of the file password.

In addition to the English letters, numbers, but also the use of special characters,

To further enhance the security of the password.

In addition, only pre registered devices are allowed to access CPU,

To intercept unauthorized access to unauthorized users.

Therefore, it is important to prevent the outflow of important program assets and protect intellectual property rights.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow and motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields.

Can also be used in combination with the CPU module to achieve appropriate control.

Easy connection programming tool via ethernet.

Programming toolls (Works2 GX, Developer GX) and CPU direct connection (1 to 1),

No need to carry out the IP address settings Q64TCRTBW. And there is no need to select the cable, the straight line and the cross line can be used.

Therefore, this connection method annd the use of USB, can easily communicate with the CPU,

Even the operators are not familiar with the network settings can easily establish a connection Q64TCRTBW.

...More relevant models >>>>

Last one: MITSUBISHI Platinum resistance temperature control module Q64TCRT

Last one: MITSUBISHI Platinum resistance temperature control module Q64TCRT next one: MITSUBISHI Platinum resistance temperature control module (upgraded version) Q64TCRTN

next one: MITSUBISHI Platinum resistance temperature control module (upgraded version) Q64TCRTN

Related download