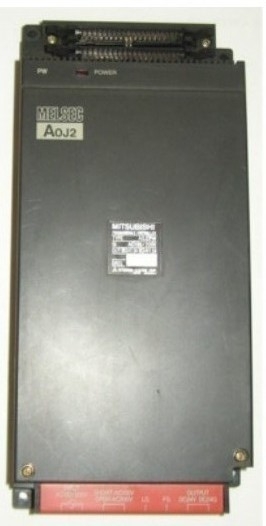

A0J2PW Power module

MITSUBISHI A0J2PW Manual And Instructions

A0J2PW datasheetPDF datasheet

MITSUBISHI A0J2PW Product information and technical parameters:

Brand: MITSUBISHI

Name: Power module

Model: A0J2PW

Input voltage range: AC100 ~ 120V/AC200 ~ 240V.

Output voltage: DC5/12V.

Output current: 2.3A/1.5A.

I/O points is an important indicator of PLC.

Reasonable selection of I/O points can not only satisfy the control requirements of the system,

And the total investment of the system is the lowest.

The input and output points and types of PLC should be determined according to the analog quantity and switch quantity of the controlled object,

Generally an input / output element to take up an input / output point.

Taking into account the future adjustment and expansion,

In general should be estimated on the total number of points plus the amount of spare 20%~30%.

The following describes the centralized control system I/O points of the estimate.

Relay output interface circuit of PLC

Working process: when the internal circuit output digital signal 1,

There is a current flowing through, the relay coil has a current, and then the normally open contact is closed,

Provide load current and voltage.

When the internal circuit outputs a digital signal 0, there is no current flowing through it,

The relay coil does not have a current, and the normally open contact is broken off,

A current or voltage that is disconnected from the load.

It is through the output interface circuit to the internal digital circuit into a signal to make the load action or not action.

...More relevant models >>>>

A0J2PW datasheetPDF datasheet

MITSUBISHI A0J2PW Product information and technical parameters:

Brand: MITSUBISHI

Name: Power module

Model: A0J2PW

Input voltage range: AC100 ~ 120V/AC200 ~ 240V.

Output voltage: DC5/12V.

Output current: 2.3A/1.5A.

I/O points is an important indicator of PLC.

Reasonable selection of I/O points can not only satisfy the control requirements of the system,

And the total investment of the system is the lowest.

The input and output points and types of PLC should be determined according to the analog quantity and switch quantity of the controlled object,

Generally an input / output element to take up an input / output point.

Taking into account the future adjustment and expansion,

In general should be estimated on the total number of points plus the amount of spare 20%~30%.

The following describes the centralized control system I/O points of the estimate.

Relay output interface circuit of PLC

Working process: when the internal circuit output digital signal 1,

There is a current flowing through, the relay coil has a current, and then the normally open contact is closed,

Provide load current and voltage.

When the internal circuit outputs a digital signal 0, there is no current flowing through it,

The relay coil does not have a current, and the normally open contact is broken off,

A current or voltage that is disconnected from the load.

It is through the output interface circuit to the internal digital circuit into a signal to make the load action or not action.

ROM capacity: 32K bytes (max 15K step).

A2A, A2A-S1, A3A, A2N, A2N-S1, A3N storage box. Position detection axis number: 1 axis.

Resolution: 4096 * 32 ~ 409.6 * 320 rotation (multi turn), 0.0039062mm/256mm ~ 0.015625mm/1024mm (linear type).

Number of output channels: 16 channels.

When communicating in the PLC network of MITSUBISHI,

There is no sense of difference and discontinuity in the network,

Can carry on the remote monitoring, modification, debugging and other work of data communication and program,

Without taking into account the level and type of network A0J2PW A0J2PW

MELSECNET/H and CC-Link use the way of loop communication,

Periodically automatically send and receive messages,

Does not require specialized data communication procedures,

Simple parameters can be set A0J2PW.

MELSECNET/H and CC-Link are used to transmit and receive the broadcast mode,

This can be done on the network data sharing.

For the use of Ethernet, MELSECNET/H, CC-Link network,

Can set the network parameters and various functions, simple and convenient in the Developer GX software screen. Output points: 32 points.

Voltage: DC12/24V A0J2PW.

OFF leakage current: 0.1mA.

Output type: transistor output (type sink).

Response time: 2ms.

16 points / a common end.

38 point terminal station.

With the surge absorber.

Each scanning process. Focus on the input signal sampling. Focus on the output signal to refresh.

Input refresh process. When the input port is closed,

Program in the implementation phase, the input end of a new state, the new state can not be read.

Only when the program is scanned, the new state is read.

A scan cycle is divided into the input sample, the program execution, the output refresh.

The contents of the component image register are changed with the change of the execution of the program.

The length of the scan cycle is determined by the three.

CPU the speed of executing instructions.

Time of instruction.

Instruction count.

Due to the adoption of centralized sampling.

Centralized output mode.

There exist input / output hysteresis phenomena, i.e., the input / output response delay.

PLC selection with the development of PLC technology, more and more types of PLC products,

Function is becoming more and more perfect, and its application is more and more extensive.

Different series of different models of PLC has different performance, applicable occasions also have different emphasis,

Price also has a greater difference. Therefore PLC selection,

Under the premise of meeting tthe control requirements,

Should consider the best performance to price ratio, a reasonable choice of PLC A0J2PW.

System program memory for storing system program,

Including management procedures, monitoring procedures, as well as the user program tto do the compiler to compile the process of interpretation A0J2PW.

Read only memory. Manufacturers use, content can not be changed, power does not disappear.

A2A, A2A-S1, A3A, A2N, A2N-S1, A3N storage box. Position detection axis number: 1 axis.

Resolution: 4096 * 32 ~ 409.6 * 320 rotation (multi turn), 0.0039062mm/256mm ~ 0.015625mm/1024mm (linear type).

Number of output channels: 16 channels.

When communicating in the PLC network of MITSUBISHI,

There is no sense of difference and discontinuity in the network,

Can carry on the remote monitoring, modification, debugging and other work of data communication and program,

Without taking into account the level and type of network A0J2PW A0J2PW

MELSECNET/H and CC-Link use the way of loop communication,

Periodically automatically send and receive messages,

Does not require specialized data communication procedures,

Simple parameters can be set A0J2PW.

MELSECNET/H and CC-Link are used to transmit and receive the broadcast mode,

This can be done on the network data sharing.

For the use of Ethernet, MELSECNET/H, CC-Link network,

Can set the network parameters and various functions, simple and convenient in the Developer GX software screen. Output points: 32 points.

Voltage: DC12/24V A0J2PW.

OFF leakage current: 0.1mA.

Output type: transistor output (type sink).

Response time: 2ms.

16 points / a common end.

38 point terminal station.

With the surge absorber.

Each scanning process. Focus on the input signal sampling. Focus on the output signal to refresh.

Input refresh process. When the input port is closed,

Program in the implementation phase, the input end of a new state, the new state can not be read.

Only when the program is scanned, the new state is read.

A scan cycle is divided into the input sample, the program execution, the output refresh.

The contents of the component image register are changed with the change of the execution of the program.

The length of the scan cycle is determined by the three.

CPU the speed of executing instructions.

Time of instruction.

Instruction count.

Due to the adoption of centralized sampling.

Centralized output mode.

There exist input / output hysteresis phenomena, i.e., the input / output response delay.

PLC selection with the development of PLC technology, more and more types of PLC products,

Function is becoming more and more perfect, and its application is more and more extensive.

Different series of different models of PLC has different performance, applicable occasions also have different emphasis,

Price also has a greater difference. Therefore PLC selection,

Under the premise of meeting tthe control requirements,

Should consider the best performance to price ratio, a reasonable choice of PLC A0J2PW.

System program memory for storing system program,

Including management procedures, monitoring procedures, as well as the user program tto do the compiler to compile the process of interpretation A0J2PW.

Read only memory. Manufacturers use, content can not be changed, power does not disappear.

...More relevant models >>>>

Related download

Last one:

Last one:  next one:

next one: