Home

>> Products

>> MITSUBISHI

>> Ans/QnAs series PLC

>> Bottom plate / expansion floor / extension cable

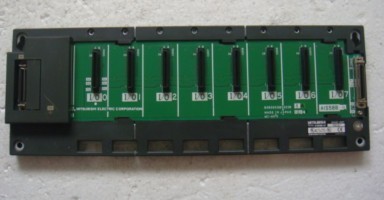

>> A1S58B-S1 Extended substrate

A1S58B-S1 Extended substrate

MITSUBISHI A1S58B-S1 Manual And Instructions

A1S58B-S1 datasheetPDF datasheet

MITSUBISHI A1S58B-S1 Product information and technical parameters:

Brand: MITSUBISHI

Name: Extended substrate

Model: A1S58B-S1

I/O slots: 8 slots.

Can you install the power module.

Outline dimension: 365*130.

There are two types of extended floor,

A power module can be inserted, and the other one is not.

The choice of any type of substrate depends on the total DC5V current consumption and the power supply on the CPU main substrate.

If the total demand is less than the power output, no additional power supply,

Then you can choose a more economical expansion board.

Both ends of the main base plate of the CPU have an expansion interface, and can be used for extending the cable connection.

...More relevant models >>>>

A1S58B-S1 datasheetPDF datasheet

MITSUBISHI A1S58B-S1 Product information and technical parameters:

Brand: MITSUBISHI

Name: Extended substrate

Model: A1S58B-S1

I/O slots: 8 slots.

Can you install the power module.

Outline dimension: 365*130.

There are two types of extended floor,

A power module can be inserted, and the other one is not.

The choice of any type of substrate depends on the total DC5V current consumption and the power supply on the CPU main substrate.

If the total demand is less than the power output, no additional power supply,

Then you can choose a more economical expansion board.

Both ends of the main base plate of the CPU have an expansion interface, and can be used for extending the cable connection.

10BASE-T

MITSUBISHI PLC is the main product in the production of MITSUBISHI motor in Dalian.

It uses a kind of programmable memory for its internal storage procedures,

Execute logic operation, sequence control, timing, counting and arithmetic operations, user oriented instruction,

And through digital or analog input / output control of various types of machinery or production process A1S58B-S1.

When the programmer input programinto the user program memory,

Then CPU according to the function of the system (the system program memory to explain the compiler),

Translate the user program into PLC internally recognized by the user to compile the program A1S58B-S1 Output type: transistor source / drain type.

Output points: 8 points A1S58B-S1.

Load voltage: DC5/12/24/48.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 1.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order A1S58B-S1.

So, sometimes also known as the order control.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. Reader writer 1 channel connection, AnSCPU/QnASCPU.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence number (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next round of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence numberr (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next rround of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work A1S58B-S1 A1S58B-S1.

MITSUBISHI PLC is the main product in the production of MITSUBISHI motor in Dalian.

It uses a kind of programmable memory for its internal storage procedures,

Execute logic operation, sequence control, timing, counting and arithmetic operations, user oriented instruction,

And through digital or analog input / output control of various types of machinery or production process A1S58B-S1.

When the programmer input programinto the user program memory,

Then CPU according to the function of the system (the system program memory to explain the compiler),

Translate the user program into PLC internally recognized by the user to compile the program A1S58B-S1 Output type: transistor source / drain type.

Output points: 8 points A1S58B-S1.

Load voltage: DC5/12/24/48.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 1.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order A1S58B-S1.

So, sometimes also known as the order control.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. Reader writer 1 channel connection, AnSCPU/QnASCPU.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence number (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next round of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence numberr (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next rround of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work A1S58B-S1 A1S58B-S1.

...More relevant models >>>>

Last one: MITSUBISHI Extended bottom plate A1S55B-S1

Last one: MITSUBISHI Extended bottom plate A1S55B-S1 next one: MITSUBISHI Expansion substrate capable of mounting power supply A1S65B-S1

next one: MITSUBISHI Expansion substrate capable of mounting power supply A1S65B-S1

Related download