Home

>> Products

>> MITSUBISHI

>> Servo driver/Servo motor

>> MR-J3 series

>> HF- (KP/SP/MP/JP) /HC- (LP/RP/UP) /HA-LP motor

>> HF-SP102 Medium inertia power servo motor

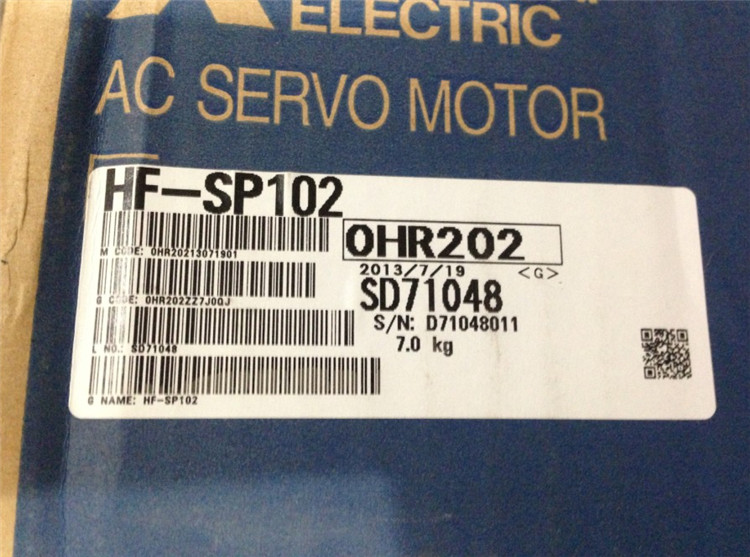

HF-SP102 Medium inertia power servo motor

MITSUBISHI HF-SP102 Manual And Instructions

HF-SP102 datasheetPDF datasheet

MITSUBISHI HF-SP102 Product information and technical parameters:

Brand: MITSUBISHI

Name: Medium inertia power servo motor

Model: HF-SP102

Servo motor series: medium inertia, medium power.

Rated output: 1.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: No.

Shaft end specification: Standard (straight axis).

Characteristics: medium inertia has two types of low speed and high speed, suitable for different applications.

IP level: IP67.

Application example:

1, material handling system.

2, industrial robots.

3, X-Y working table.

The protection level of the HF-SP/HF-JP series servo motor is IP67 (except the shaft part).

Motor capacity selection soft (MRZJW3-MOTSZ111E)

Friendly interface design, only in the mechanical description window input constant and operation mode can choose the best servo amplifier,

The servo motor and the regenerative braking options, but also in the selection window in the selection of linear servo motor and direct drive motor.

Characteristic

(1) 10 typical mechanical transmission structure can be used to choose

(2) user defined operating modes (location and speed control)

(3) in the selection process, the feed speed and torque can be displayed in a graphical format.

(4) the calculation process can be displayed

Can easily calculate the power of the servo motor free software!

...More relevant models >>>>

HF-SP102 datasheetPDF datasheet

MITSUBISHI HF-SP102 Product information and technical parameters:

Brand: MITSUBISHI

Name: Medium inertia power servo motor

Model: HF-SP102

Servo motor series: medium inertia, medium power.

Rated output: 1.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: No.

Shaft end specification: Standard (straight axis).

Characteristics: medium inertia has two types of low speed and high speed, suitable for different applications.

IP level: IP67.

Application example:

1, material handling system.

2, industrial robots.

3, X-Y working table.

The protection level of the HF-SP/HF-JP series servo motor is IP67 (except the shaft part).

Motor capacity selection soft (MRZJW3-MOTSZ111E)

Friendly interface design, only in the mechanical description window input constant and operation mode can choose the best servo amplifier,

The servo motor and the regenerative braking options, but also in the selection window in the selection of linear servo motor and direct drive motor.

Characteristic

(1) 10 typical mechanical transmission structure can be used to choose

(2) user defined operating modes (location and speed control)

(3) in the selection process, the feed speed and torque can be displayed in a graphical format.

(4) the calculation process can be displayed

Can easily calculate the power of the servo motor free software!

Motor: HA-SH type.

Power: 1.5kw.

Speed: 3000r/min.

The speed regulating motor can be divided into a constant speed motor, a stepless constant speed motor, a stepless speed changing motor and a stepless speed changing motor,

Can also be divided into electromagnetic induction motor, DC motor, PWM variable frequency motor and switched reluctance motor HF-SP102.

The rotor speed of the induction motor is always slightly lower than that of the rotating magnetic field HF-SP102

The rotor speed of the synchronous motor is not independent of the load size, but is always maintained as a synchronous speed. Drive: MR-H_AN series.

Rated output: 22KW.

Universal AC servo.

Servo driver (drives servo) also known as the "servo controller", "servo amplifier",

Is a kind of controller used to control the servo motor HF-SP102. Its function is similar to that of the frequency converter,

Belongs to a part of the servo system, which is mainly used in high precision positioning system.

In general, the servo motor is controlled by position, speed and torque in three ways,

To achieve high precision positioning of the transmission system, the current transmission technology is the high-end products HF-SP102.

Servo drive is an important part of modern motion control,

Is widely used in industrial robots and CNC machining centers and other automation equipment.

In particular, it has become a hot research topic in the field of servo drives for the control of AC permanent magnet synchronous motor.

Current, speed and position 3 closed loop control algorithm based on vector control is widely used in AC servo drive system.

The speed closed-loop design of the algorithm is reasonable or not, for the entire servo control system,

Especially the speed control performance plays a key role.Servo motor series: low inertia, small capacity.

Rated output: 2.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: there.

Oil seal: have.

Corresponding servo amplifier: MR-JE-10B/MR-JE-10A.

Support position control, speed control, torque control, push and press control.

Position control can use linear, arc interpolation controller, fixed size feed control, target position change and other rich functions.

The position control and torque controol are realized by switching control mode HF-SP102.

The gain adjustment of servo can be simply performed by the advanced one key tuning function.

At the same time, it is also able to suppress the low frequency vibration of the manipulator by the advvanced vibration suppression control II,

Shorten the time to complete the positioning, so as to achieve the production of the rhythm of the shortening HF-SP102.

Power: 1.5kw.

Speed: 3000r/min.

The speed regulating motor can be divided into a constant speed motor, a stepless constant speed motor, a stepless speed changing motor and a stepless speed changing motor,

Can also be divided into electromagnetic induction motor, DC motor, PWM variable frequency motor and switched reluctance motor HF-SP102.

The rotor speed of the induction motor is always slightly lower than that of the rotating magnetic field HF-SP102

The rotor speed of the synchronous motor is not independent of the load size, but is always maintained as a synchronous speed. Drive: MR-H_AN series.

Rated output: 22KW.

Universal AC servo.

Servo driver (drives servo) also known as the "servo controller", "servo amplifier",

Is a kind of controller used to control the servo motor HF-SP102. Its function is similar to that of the frequency converter,

Belongs to a part of the servo system, which is mainly used in high precision positioning system.

In general, the servo motor is controlled by position, speed and torque in three ways,

To achieve high precision positioning of the transmission system, the current transmission technology is the high-end products HF-SP102.

Servo drive is an important part of modern motion control,

Is widely used in industrial robots and CNC machining centers and other automation equipment.

In particular, it has become a hot research topic in the field of servo drives for the control of AC permanent magnet synchronous motor.

Current, speed and position 3 closed loop control algorithm based on vector control is widely used in AC servo drive system.

The speed closed-loop design of the algorithm is reasonable or not, for the entire servo control system,

Especially the speed control performance plays a key role.Servo motor series: low inertia, small capacity.

Rated output: 2.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: there.

Oil seal: have.

Corresponding servo amplifier: MR-JE-10B/MR-JE-10A.

Support position control, speed control, torque control, push and press control.

Position control can use linear, arc interpolation controller, fixed size feed control, target position change and other rich functions.

The position control and torque controol are realized by switching control mode HF-SP102.

The gain adjustment of servo can be simply performed by the advanced one key tuning function.

At the same time, it is also able to suppress the low frequency vibration of the manipulator by the advvanced vibration suppression control II,

Shorten the time to complete the positioning, so as to achieve the production of the rhythm of the shortening HF-SP102.

...More relevant models >>>>

Last one: MITSUBISHI Medium inertia power servo motor HF-SP52

Last one: MITSUBISHI Medium inertia power servo motor HF-SP52 next one: MITSUBISHI Medium inertia power servo motor HF-SP152

next one: MITSUBISHI Medium inertia power servo motor HF-SP152

Related download