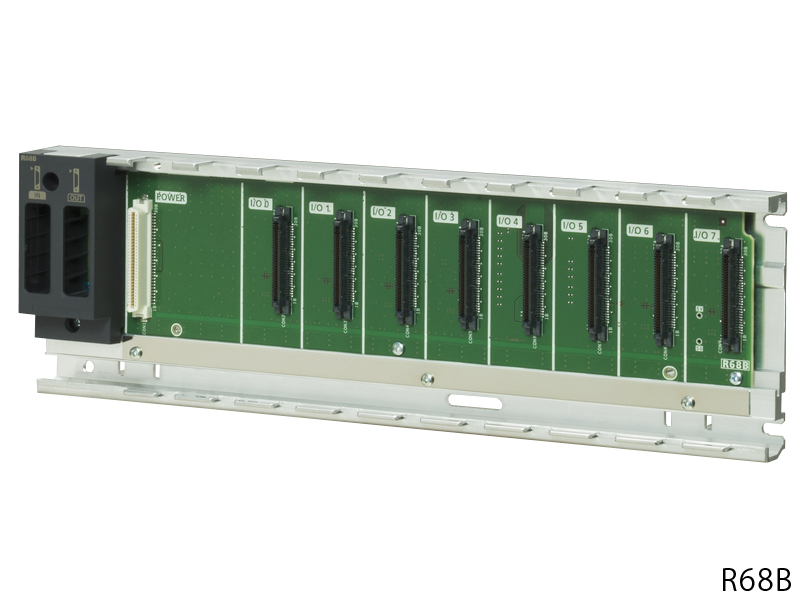

R68B Extended substrate

MITSUBISHI R68B Manual And Instructions

R68B datasheetPDF datasheet

MITSUBISHI R68B Product information and technical parameters:

Brand: MITSUBISHI

Name: Extended substrate

Model: R68B

The input and output module installation number: 8.

Can install module: iQ-R MELSEC series module.

DIN guide rail mounting adapter type: R6DIN1.

Size (H) * (32.5mm) * (W) * (D): * 328mm * 101mm.

Substrate module for mounting various modules of iQ-R MELSEC series.

CPU module could not be installed on the extended substrate module. "

...More relevant models >>>>

R68B datasheetPDF datasheet

MITSUBISHI R68B Product information and technical parameters:

Brand: MITSUBISHI

Name: Extended substrate

Model: R68B

The input and output module installation number: 8.

Can install module: iQ-R MELSEC series module.

DIN guide rail mounting adapter type: R6DIN1.

Size (H) * (32.5mm) * (W) * (D): * 328mm * 101mm.

Substrate module for mounting various modules of iQ-R MELSEC series.

CPU module could not be installed on the extended substrate module. "

"Input points: 16 points.

Rated input voltage and frequency: DC24V.

Rated input current: TYP 7.0mA.

Response time: 0.1 ~ 70ms.

Common way: 16 point / public end.

Interrupt function: have.

External wiring connection mode: 18 point screw terminal.

The input and output module is the interface between the switch, sensor, actuator, and other control system of the ON/OFF signal processing R68B.

Compared with the previous series, iQ-R MELSEC series of input and output modules have more features,

1 modules can be used for a variety of purposes, to help reduce the cost of deployment and maintenance costs R68B

The module design of the pursuit of convenience".

Paste the white label on the input module and paste the red label on the output module,

The rated specifications are clearly marked on the front of the module, which can prevent the use of errors R68B.

The input and output number stamped on the top of the front display input and output module LED, can easily confirm the status of the ON/OFF.

The terminal arrangement of each signal is recorded on the wiring terminal of the 16 point module, and the false wiring can be prevented R68B.

The 64 point module can be 32 points as the unit, through the switch to switch to display the input and output number.

In addition, serial number tag in the front of the module, can be easily recognized. ""Database sharing.

FA integration solution "e-F@ctory" to achieve development, production, and maintenance of the various stages of the "TCO reduction" as the primary goal,

Effectively utilize advanced technology, optimize the environment of the factory, and explore the future of manufacturing industry.

As the core component of the "e-F@ctory" information sharing products, MES interface through the shared control system and IT system database,

Achieve production efficiency, product quality improvement.

The information collected from the production site is sent directly to the database.

Conditions can monitor the event data in the MES interface side, in the conditions established, send to the database information of work performance data of IT system.

In addition, the MES interface can be used to read data from the database, such as job instructions.

System construction costs reduced by 65%.

Through the use of MES interface, can be directly connected to the programmmable controller and database, simplifying the system structure R68B.

In addition, there is no need to use the gateway computer and the program at the time of connection, so compared with the past,

When the system is constructed, the work time and tthe time limit for a project are reduced R68B. And, by using the high reliability of MES interface,

Can reduce the computer maintenance, maintenance costs. "

Rated input voltage and frequency: DC24V.

Rated input current: TYP 7.0mA.

Response time: 0.1 ~ 70ms.

Common way: 16 point / public end.

Interrupt function: have.

External wiring connection mode: 18 point screw terminal.

The input and output module is the interface between the switch, sensor, actuator, and other control system of the ON/OFF signal processing R68B.

Compared with the previous series, iQ-R MELSEC series of input and output modules have more features,

1 modules can be used for a variety of purposes, to help reduce the cost of deployment and maintenance costs R68B

The module design of the pursuit of convenience".

Paste the white label on the input module and paste the red label on the output module,

The rated specifications are clearly marked on the front of the module, which can prevent the use of errors R68B.

The input and output number stamped on the top of the front display input and output module LED, can easily confirm the status of the ON/OFF.

The terminal arrangement of each signal is recorded on the wiring terminal of the 16 point module, and the false wiring can be prevented R68B.

The 64 point module can be 32 points as the unit, through the switch to switch to display the input and output number.

In addition, serial number tag in the front of the module, can be easily recognized. ""Database sharing.

FA integration solution "e-F@ctory" to achieve development, production, and maintenance of the various stages of the "TCO reduction" as the primary goal,

Effectively utilize advanced technology, optimize the environment of the factory, and explore the future of manufacturing industry.

As the core component of the "e-F@ctory" information sharing products, MES interface through the shared control system and IT system database,

Achieve production efficiency, product quality improvement.

The information collected from the production site is sent directly to the database.

Conditions can monitor the event data in the MES interface side, in the conditions established, send to the database information of work performance data of IT system.

In addition, the MES interface can be used to read data from the database, such as job instructions.

System construction costs reduced by 65%.

Through the use of MES interface, can be directly connected to the programmmable controller and database, simplifying the system structure R68B.

In addition, there is no need to use the gateway computer and the program at the time of connection, so compared with the past,

When the system is constructed, the work time and tthe time limit for a project are reduced R68B. And, by using the high reliability of MES interface,

Can reduce the computer maintenance, maintenance costs. "

...More relevant models >>>>

Related download

Last one:

Last one:  next one:

next one: