Home

>> Products

>> MITSUBISHI

>> Inverter

>> Inverter accessories

>> FR-CV-7.5K Common DC bus converter

FR-CV-7.5K Common DC bus converter

MITSUBISHI FR-CV-7.5K Manual And Instructions

FR-CV-7.5K datasheetPDF datasheet

FR-CV-7.5K Instruction manual

MITSUBISHI FR-CV-7.5K Product information and technical parameters:

Brand: MITSUBISHI

Name: Common DC bus converter

Model: FR-CV-7.5K

Power: 7.5kw.

Voltage: 200V.

There are 100% braking torque output in continuous regeneration, which can correspond to the continuous regeneration operation of the pipeline control.

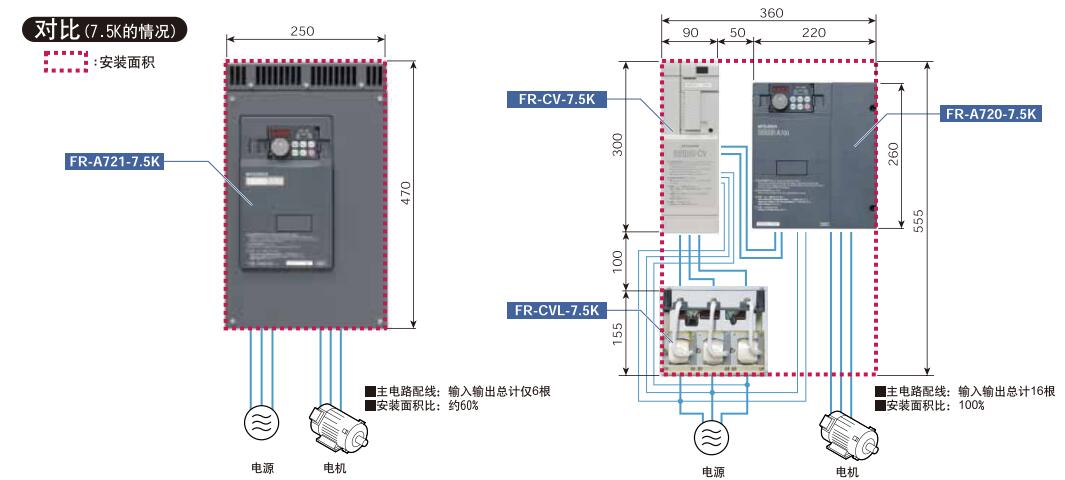

There is no need to install the braking unit for each frequency converter, which can reduce the comprehensive space and reduce the comprehensive cost.

Renewable energy can be used for other frequency converter, excess energy back to the grid, to achieve energy saving.

...More relevant models >>>>

FR-CV-7.5K datasheetPDF datasheet

FR-CV-7.5K Instruction manual

MITSUBISHI FR-CV-7.5K Product information and technical parameters:

Brand: MITSUBISHI

Name: Common DC bus converter

Model: FR-CV-7.5K

Power: 7.5kw.

Voltage: 200V.

There are 100% braking torque output in continuous regeneration, which can correspond to the continuous regeneration operation of the pipeline control.

There is no need to install the braking unit for each frequency converter, which can reduce the comprehensive space and reduce the comprehensive cost.

Renewable energy can be used for other frequency converter, excess energy back to the grid, to achieve energy saving.

MITSUBISHI inverter series: FR-A820.

Voltage level: three phase 200V.

Power: 55kw.

SLD converter rated current: 316A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight) FR-CV-7.5K.

Type load) for selection FR-CV-7.5K

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable FR-CV-7.5K.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Power: 30kw.

Voltage: 200V.

Purpose: high frequency braking resistor.

The braking ability provided by the braking capacity is larger than that provided by the external braking resistor FR-CV-7.5K.

Can also be connected without built-in brake transistor inverter.

Three types of discharge resistors are available.

Please select according to the required braking torque. MITSUBISHI inverter series: FR-F820.

Voltage level: three phase 200V.

Power: 37kw.

SLD converter rated current: 187A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

PID target value can be set directly from the operator panel. Flexible change settings.

In the 1 inverter, through the PID control of parallel connection pump (up to 4 units) can adjust the amount of water and so on.

1 pumps driven by parallell connection of the pump machine, in addition to the pump for power frequency drive FR-CV-7.5K.

The number of power frequency driven pump, according to the automatic adjustment of water.

The liquid crystal panel options (FR-LU08) can be converted too a more intuitive display unit% units FR-CV-7.5K.

Through the use of wind, temperature and other familiar units can be simple to maintain and adjust the display.

Voltage level: three phase 200V.

Power: 55kw.

SLD converter rated current: 316A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight) FR-CV-7.5K.

Type load) for selection FR-CV-7.5K

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable FR-CV-7.5K.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Power: 30kw.

Voltage: 200V.

Purpose: high frequency braking resistor.

The braking ability provided by the braking capacity is larger than that provided by the external braking resistor FR-CV-7.5K.

Can also be connected without built-in brake transistor inverter.

Three types of discharge resistors are available.

Please select according to the required braking torque. MITSUBISHI inverter series: FR-F820.

Voltage level: three phase 200V.

Power: 37kw.

SLD converter rated current: 187A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

PID target value can be set directly from the operator panel. Flexible change settings.

In the 1 inverter, through the PID control of parallel connection pump (up to 4 units) can adjust the amount of water and so on.

1 pumps driven by parallell connection of the pump machine, in addition to the pump for power frequency drive FR-CV-7.5K.

The number of power frequency driven pump, according to the automatic adjustment of water.

The liquid crystal panel options (FR-LU08) can be converted too a more intuitive display unit% units FR-CV-7.5K.

Through the use of wind, temperature and other familiar units can be simple to maintain and adjust the display.

...More relevant models >>>>

Last one: MITSUBISHI Brake resistance FR-BR-H55K

Last one: MITSUBISHI Brake resistance FR-BR-H55K next one: MITSUBISHI Common DC bus converter FR-CV-11K

next one: MITSUBISHI Common DC bus converter FR-CV-11K

Related download